Giving infrared sight to JWST

A number of the Loxham staff were significantly involved in manufacturing many of the mirrors employed in the JWST. We present here a short story about how the CUPE Nion Nanocentre ultra precision machine created by Pat McKeown and Keith Carlisle gave Cranfield University a unique capability for diamond turning super sharp edge micro-mirror arrays, and that Paul Shore and Paul Morantz manufactured the JWST MIRI spectrometer imager mirrors.

Written by

Paul Shore, FREng and Pat McKeown OBE, FREng

This month the most important space telescope since Hubble was launched.

The James Webb Space Telescope (JWST) will be an unprecedented scientific instrument seeing deeper into the universe than any of its predecessors. This engineering marvel has many critical innovations and will have many threads of engineering esteem in its realisation.

This article presents how our leading Ultra Precision Engineers produced 132 of the 570 mirror surfaces employed within the JWST.

Introduction

The JWST, the replacement for the Hubble Space Telescope, was launched on the 25th December 2021. It promises to enable a step change capability to observe and analyse the universe. At 7 times the size of the Hubble Space Telescope its light collecting capability represents an order of magnitude sensitivity enhancement.

Unlike the Hubble space telescope which orbits the Earth, the JWST will orbit the Sun 1 million miles from Earth. There is no opportunity for astronauts to perform maintenance and corrections to the JWST. It is a fully robotic and highly complex telescope having 4 major instruments. It has a staggering number of optical surfaces: in the order of 570 mirrors. Although not the largest of them almost half of the JWST mirrors are installed within its Mid Infrared Instrument (MIRI).

The JWST MIRI instrument was developed by the UK Astronomy Technology Centre in Edinburgh, who entrusted the Precision Engineering Institute at Cranfield University to manufacture the high complexity image slicers and re-imager mirrors – all 132 mirror surfaces.

More of JWST mirrors were made in Cranfield than any other location, and produced on an ultra precision CNC machine tool designed and manufactured at Cranfield.

JSWT MIRI Mirrors

A critical mirror requirement of the MIRI instrument is its image slicers and re-imager mirror arrays. These highly complex mirrors perform a specific light handling task that creates a so-called “data cube”. It is these “data cubes” that enable astronomers to examine for example the atmospheres of Earth-like planets located nearby distant stars.

An animation of the lightpath of MIRI can be seen at: https://www.esa.int/ESA_Multimedia/Videos/2021/09/Webb_MIRI_spectroscopy_animation

The image slicers and re-imagers of MIRI are uniquely different to those that have previously been employed in ground-based telescopes. Previously such complex optical systems had been created by assembling individual segments of mirrors and fixing them together to create arrays. This multi component assembly approach was not thought suitable for a space telescope needing to withstand an ESA Arianne 5 launch and having an operation location of 1 million miles from Earth.

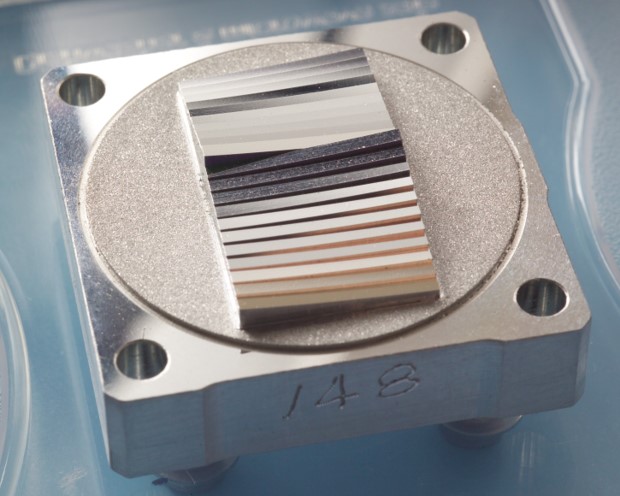

UK ATC contracted Cranfield’s precision engineers and their unique ultra-precision machinery to develop and manufacture monolithic construction image slicers and re-imagers. Each of the 4 image slicers have up to 22 mirrors and each of the 8 re-imagers have up to 11 mirrors. All mirror surfaces were required to nanometre levels of accuracy in terms of shape and smoothness. Each of the mirrors needed to be precisely located with respect to each other to micrometre accuracy levels. Most critically the sharpness of the edge of all the mirrors needed to be super sharp in order to prevent stray-light being generated that would degrade the overall imaging performance.

To fabricate such highly complex and precise mirrors a machine tool having unprecedented levels of long-term accuracy would be required.

Cranfield NION Nanocentre

The Cranfield NION Nanocentre, the World’s most accurate CNC machine tool of it size in 2005, was used to manufacture all the MIRI image slicers and re-imagers.

The NION machine was design and developed at Cranfield between 1988 – 1992. It was funded under the UK’s Department for Trade and Industry LINK National Initiative on Nanotechnology (NION) programme administered by the National Physical Laboratory.

NION employs a number of ultra precision technologies that made it ideal for fabricating the MIRI mirrors. It uses a laser interferometer-based metrology frame operating at 1 nanometre resolution together with an enhanced optical imaging system offering near nanometre levels of tool edge determination. A sophisticated thermal control system ensures all parts of the machine are maintained at 20°C with an operating resolution of 0.001°C and accuracy of 0.01°C. Machine motions were also levitated on pressurised oil films so there was no mechanical contact ensuring ultra smooth motions were achieved.

Consequently, the NION machine could maintained sub-micrometre levels of position accuracy over many hours whilst mirror manufacturing. It made NION the ideal machine for fabricating the complex MIRI monolithic mirror arrays.

Kelvin inspired tooling technology

The NION is an extremely accurate 3 axes lathe. However, the highly complex geometries of the JWST slicers and re-imagers demanded that their substrates were precisely positioned and then repositioned between each mirror surface production process. To facilitate this need Cranfield developed a tooling technology having in built metrology surfaces that provided a cylindrical reference frame. From this metrology reference frame the optical “origins” of the imager slicers and re-imagers were super precisely positioned. The clamping technology used in these tooling “drums” was based on kinematic concepts originally reported by Lord Kelvin and James Clerk Maxwell. These kinematic methods ensured micrometre levels of repeatable repositioning.

Measuring MIRI mirrors

Assurance of telescope mirror quality is a paramount responsibility. To ensure the MIRI slicers and re-imagers were correct a specially defined measuring technique was developed by the Cranfield team. The technique employed a miniature laser interferometer that was mounted onto an ultra-precision co-ordinate measuring machine. By using master spherical surfaces of known and traceable radius of curvature, and optical straight edges of known and traceable flatness, each of the MIRI mirror surfaces were measured for shape and their relative array positioning in three directions.

Validation system testing performed by the UK ATC of the assembled MIRI instrument verified that the Cranfield made MIRI mirrors were correct.

Cranfield contribution to the JWST

Cranfield developed the manufacturing capability and manufactured all the MIRI spectrometer mirrors. This amounted to 132 flight mirrors on 24 substrate components, together with a full set of Flight spares.

The development of the JWST MIRI optics, from initial breadboard samples, through the Verification samples and onto the delivery of the Flight, and Flight Spares, was performed by the Cranfield team within a 3-year period.

Acknowledgments

The authors would like to credit their collaboration work with David Lee and Phil Parr-Burman of the UK ATC, and their Cranfield colleagues: Alan Heaume, Keith Carlisle, Paul Morantz, Richard May-Miller, Roger Read, and the late Bills Wills-Moren.

The NION-Nanocentre project was managed by the authors through the Cranfield Unit for Precision Engineering (CUPE) together with Cranfield spin out companies: Cranfield Precision Engineering Ltd and Cranfield Precision Systems Ltd.

The manufacture of the JWST MIRI image slicers and re-imager mirrors was managed by the authors as Professors at Cranfield University.

Notes

The UK's Department for Trade and Industry is now called the Department for Business Energy and Industrial Strategy