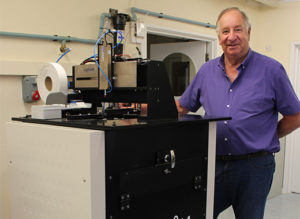

μ6 Turn/Mill represents a unique combination diamond turning and micro milling system.

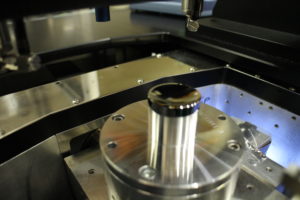

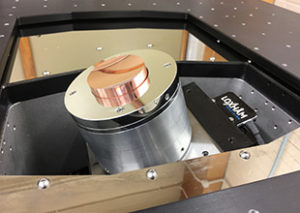

The µ6 Turn/Mill employs a highly integrated design employs low moving masses, friction free air bearings, miniaturized electronics, automation and thermal control.

μ6 offers small component manufacturers of watch, optics, medical and print head devices automated diamond turning and micro milling capabilities within a single machine system.

Operation of μ6 requires only single phase electricity and clean dry compressed air. A temperature controlled water supply provides necessary temperature control.

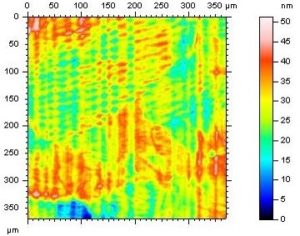

Although small, highly economical to run, house and transport the μ6 Turn/Mill is a fully capable diamond turning and micro-milling production system offering unprecedented productivity and quality levels.

Comments are closed.