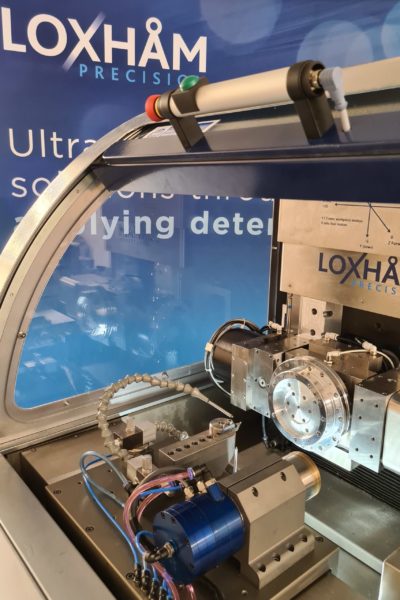

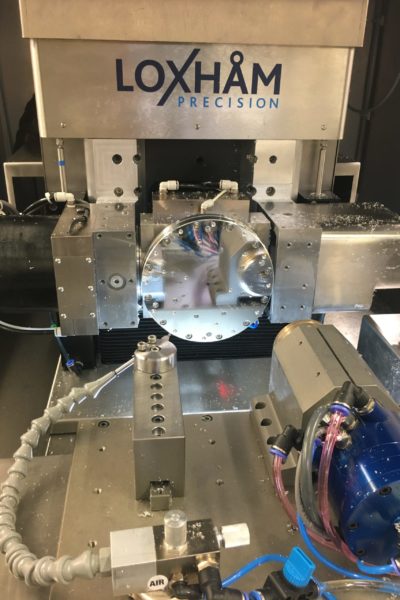

μ5 Turn/Mill represents a new era ultra precision turning and micro milling system.

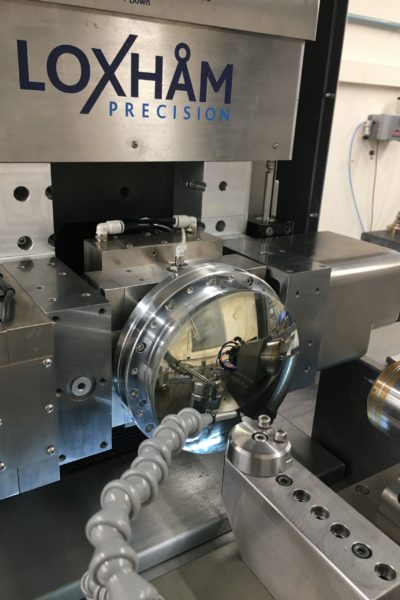

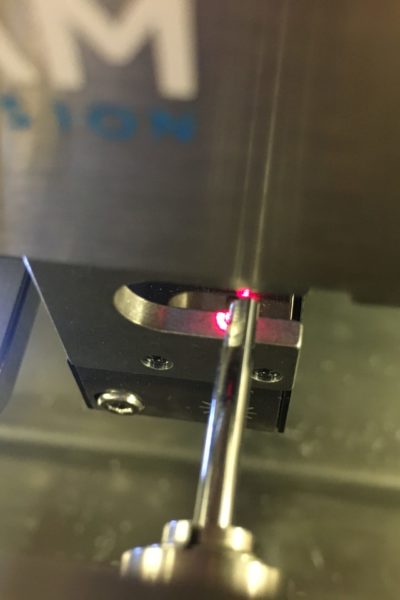

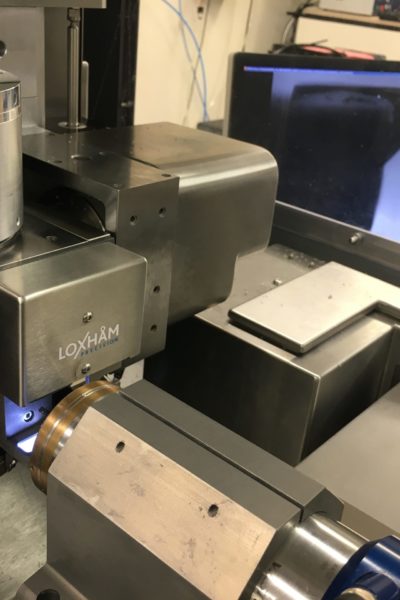

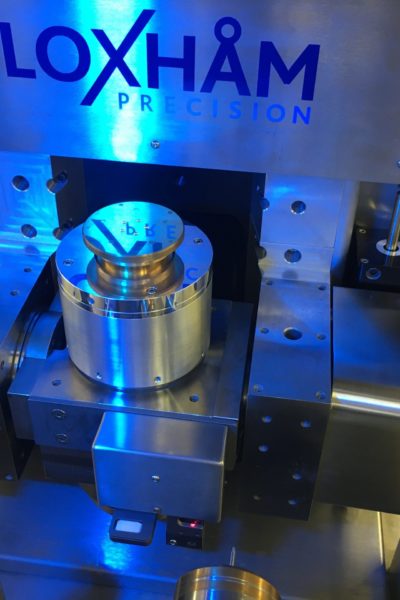

The µ5 Turn/Mill is a compact and low energy demanding 5 AXIS CNC ultra precision machine tool offering full CAM compliant machining modes. It employs Loxham's own low pressure oil hydrostatic linear slideways with low moving masses, friction free air spindle bearings, miniaturized electronics with active thermal control.

μ5 fits through a standard office doorway and weighs approximately 700kg making its installation and repositioning a very simple activity. The whole machine system, including water cooling unit, operates from a single phase 200V 13 amp power socket.

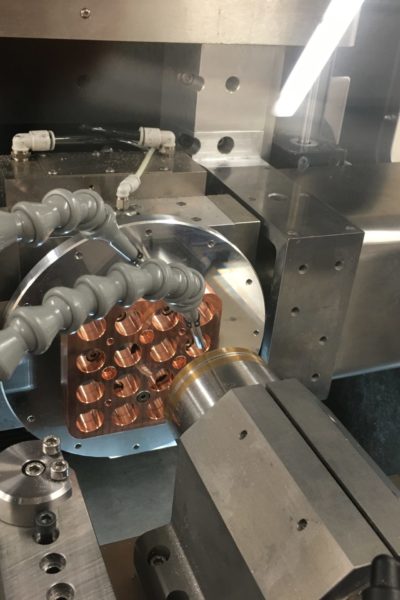

μ5 is highly suitable for small and medium sized batch manufacturing where complex shape finishing is demanded. Manufacturers wishing to finish additive manufactured parts, diamond machining of electro-optics, micromachining of quantum devices, medical components and watch parts will be interested to examine the μ5 machine tool.

Although small, highly economical to run, house and transport the μ5 Turn/Mill is a fully CAM capable diamond turning and micro-machining production system.

Comments are closed.